Inductive Hardening

Inductive Hardening – Efficient Hardening

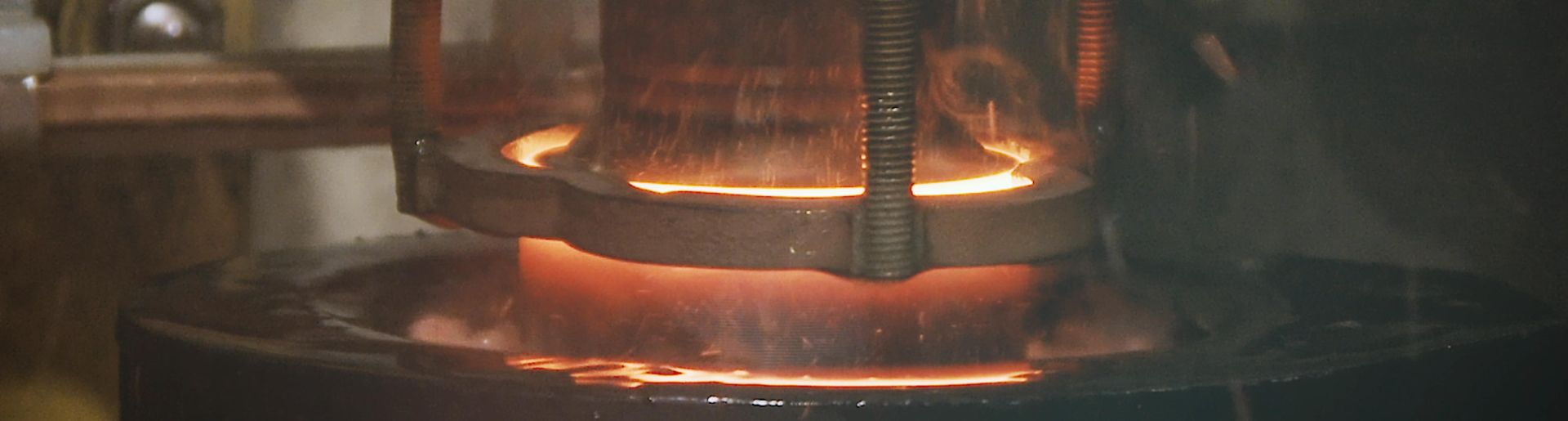

Steel is hardened by heating and then subsequent controlled cooling. In this day and age many different methods are used, each with its advantages and disadvantages. Indulaser specializes in edge hardening – thus it will only harden a particular region, and not the whole piece.

Whenever warpage and precision play a role, edge hardening is superior to other methods. Through various diverse methods, Indulaser has specialized in the Inductive heating of the parts and long-standing experience and expertise.

Less Distortion – i.e. in Grooved End-Pieces

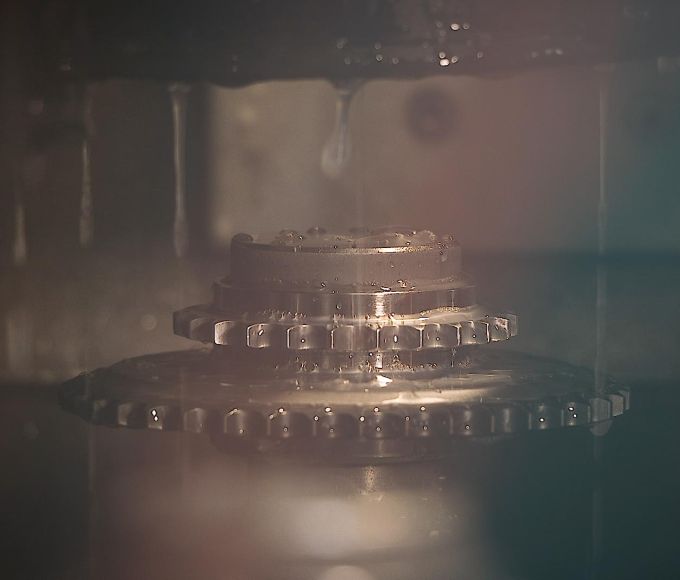

Indulaser has a leading role in the minimization of the proportion between heated and untreated mass. The less mass that is heated, the less tension differences there are in the material; thus the risks of tension cracks drastically sink. Grooved end-pieces of camshafts in superior hardness quality with minimal distortion testify to our innovative solutions.

Indulaser’s leadership in the field of edge hardening was achieved not only through exceptional material and production expertise of experienced employees, but also thanks to the development department of our company. Computer-assisted service and frequency range modulations allow for exceptional hardening depths as well as exact contoured hardening, which in turn allows engine and transmission manufacturers to create completely new designs.

A large portion of automobiles produced in Europe already contain parts hardened by Indulaser. Thanks to excellent quality and consistency in inductive edge hardening, this is also true of an increasing number of automobiles manufactured in Asia.

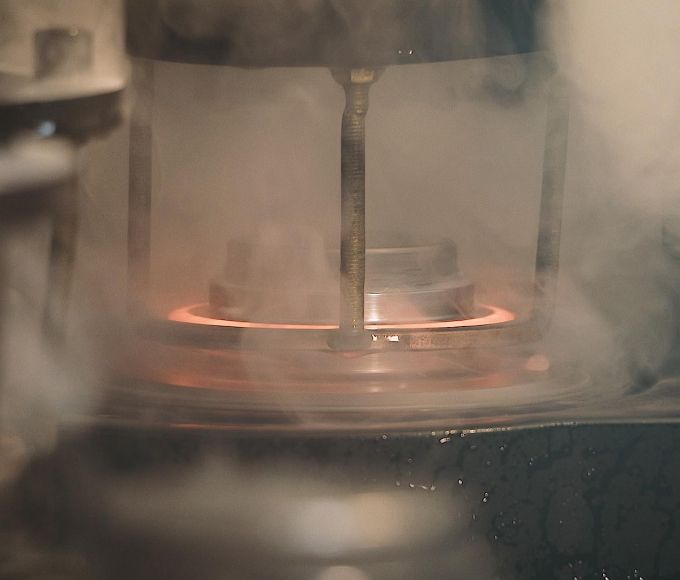

Annealing

Through annealing, tensions can be reduced and the subsequent processing can be greatly simplified (softer parts are less worn in use). Due to the pure inductive heating of the

parts, Indulaser can make very competitive offers, whereby the total price of the processed part can be reduced for customers and the competitiveness can be increased.