QUALITY ASSURANCE & LABORATORY

Crack Detection

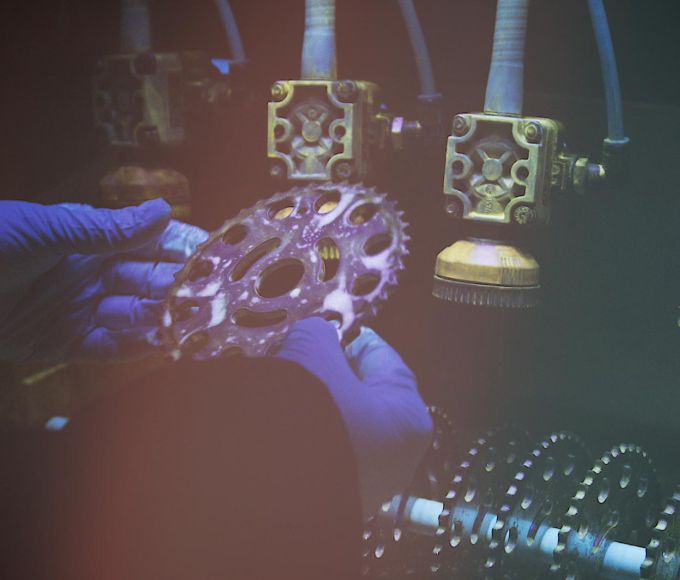

Indulaser implemented a crack detection test with magnetic powder

and facilitated the development of a crack detection procedure.

Visual inspections

Through outsourced test areas and optimal environmental conditions, we can offer a 100% visual final inspection of customer products. The visual inspection of components is another non-destructive testing method and enables the detection of "defects" that cannot be detected by fluorescent crack detection, for example.

Damage Analysis

Indulaser is able to conduct metallurgical microstructure analyses. These far-reaching assessments evaluate material characteristics and potential changes.

Highest Quality

A cutting-edge laboratory and constantly increasing quality standards combine to achieve the highest level of process security possible. As a regularly-audited supplier to the automobile industry, Indulaser meets the highest standards and through optimal documented processes is positioned to fulfill demanding customer requirements and standards.