Home

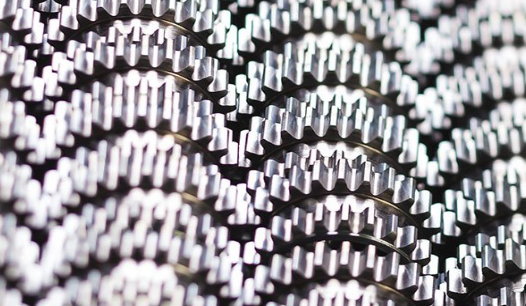

Induktionshärten

Die induktive Welt des Randschichthärtens

Induktive

Wärmebehandlung

Energiesparendes, induktives Randschicht-Härten mit eigenem Werkzeugbau und raffinierten Abläufen…

Erfahren Sie mehrSerienfertigung

Als zertifizierter Lieferant erfüllen wir die hohen Qualitätsstandards der Industrie in kleinen und grossen Volumen...

Erfahren Sie mehrPrototypen Kleinserien & Einzelteile

Einzelne Teile, Kleinserien und Prototypen-Entwicklung in enger Zusammenarbeit mit unseren Kunden…

Erfahren Sie mehrQualitätssicherung

& Labor

Internes Labor und effektive Qualitätssicherung sorgen für gleichbleibend hochstehende Qualität…

Erfahren Sie mehrWeitere Dienstleistungen

Rissprüfung, Visuelle Kontrolle, Schadensfallanalyse, Richtprozess, Verpacken und Logistik aus einer Hand…

Erfahren Sie mehrBeratung &

Entwicklung

Technische & metallurgische Beratung – Wir unterstützen unsere Kunden bei der Entwicklung und Verbesserung ihrer Teile…

Erfahren Sie mehrTeile jährlich

(EnAW)

Werkstücke

Unsere Stärke

Swiss Quality

Dank eigenem Labor und Werkzeugbau sowie innovativen Lösungen ist Indulaser der ideale Partner für Kunden aus allen Industriezweigen. ISO-9001 Zertifizierung, Rissprüfung und metallurgische Inhouse-Beurteilung bieten Gewähr, dass sämtliche Teile in gleichbleibender Qualität effizient und termingetreu gehärtet werden.

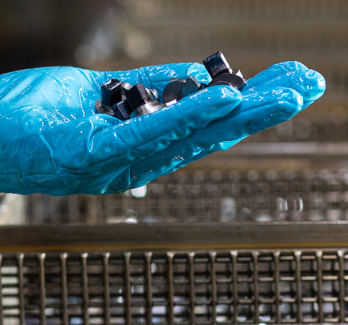

Indulaser härtet in Einzel- bis Serienfertigung gedrehte, gesinterte, gestanzte und verformte Werkstücke im Gewichtsbereich von wenigen Gramm bis in den einstelligen Tonnenbereich. Die maximale Länge richtet sich flexibel auf die gestellten Anforderungen der Aufträge.

Das Unternehmen

Die Indulaser AG ist ein mittelständisches Schweizer Unternehmen, welches sich im Bereich der Randschicht-Härtung durch Innovation und höchste Prozesssicherheit seit 2002 einen ausgezeichneten Namen erarbeitet hat.

Induktive Härterei mit Entwicklungsabteilung

Indulaser bekennt sich klar zu Schweizer Grundwerten wie Qualität, Pünktlichkeit, Zuverlässigkeit und Präzision. Dieser konsequente Fokus auf „swissness“ ist die Basis für Kundenzufriedenheit und eine prosperierende Zukunftsausrichtung.

Indulaser beschäftigt rund 30 Angestellte, der Hauptstandort befindet sich in 9323 Steinach, unweit der Deutschen und Österreichischen Grenzen.